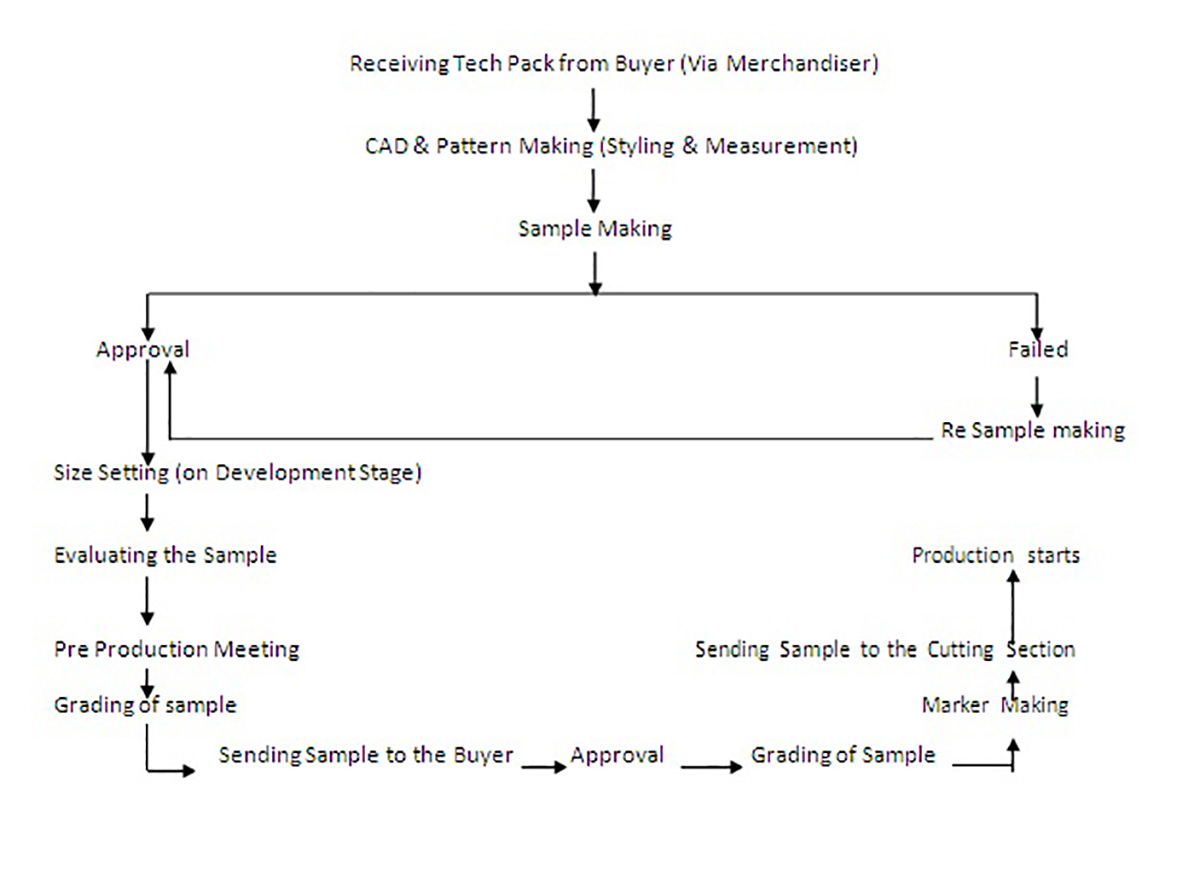

Brief Description of the Garment Sampling Process

1. Tech Pack Receiving: This is the first stage of the sampling processes. In this stage Tech Pack or the Technical pack is received from the buyer, via merchandiser. Tech pack contains all the specifications to produce a garment.

2. CAD & Pattern Making: In this stage pattern is made through CAD. Sometimes pattern is made manually, but CAD is more popular and easy, Computer-aided design (CAD) is the use of computer Technology for the design of objects, real or virtual. The design of geometric models for object shapes, in particular, is often called computer-aided geometric design (CAGD). However CAD often involves more than just shapes. As in the manual drafting of Technical and engineering drawings, the output of CAD often must convey also symbolic information such as materials, processes, dimensions, and tolerances, according to application-specific conventions. CAD may be used to design curves and figures in two-dimensional (“21”) space; or curves, surfaces, or solids in three-dimensional (“3D”) objects. Viyellatex pattern section uses Optitex CAD software for pattern making.

3. Sample Making: Sample making is the ultimate goal of this department. After making the pattern, the sample is made by using the pattern set.

4. Size Setting: After making the sample, size is set according to the Tech Pack. If there is any fault, the sample is redone.

5. Pre Production (PP) Meeting: After the buyer has inspected the sample, a pre-production meeting is called. In this meeting buyer or his agent, merchandiser, sample manager, all remain present. They decide on how to and when to start the production. If the decision Okayed, the sample is ready to go for final production.

6. Grading of Sample: After finalizing the sample. Grading is done. There may be several grades of a single design. The grading is done to separate the samples and patterns from each others

7. Marker: After grading the samples. The design is inputted into the marker software. This software specifies how to set the pattern in the actual fabric. By using the marker software efficiently, fabric can be saved. Viyellatex uses Gerber Garment Technology (GGT) for marker making.

8. Cutting: After making the marker the pattern is delivered to the cutting unit and the fabric is cut for final production.