The textile industry is currently seen as being the world’s most polluting industry. It experiences significant challenges to become greener and more sustainable.

“The fashion industry produces 20 per cent of global wastewater and 10 per cent of global carbon emissions - more than all international flights and maritime shipping combined. Textile dyeing is the second largest polluter of water globally. It takes about 2,000 gallons of water to make a typical pair of jeans.”

The textile industry is looked upon as one that is positively affecting global economic development.

Initiatives to increase the sustainability of the textile industry are being led by certifying organisations like OEKO-TEX®, GOTS and Bluesign. OEKO-TEX® for example is continuously in development of test methods and setting limit values for the textile and leather industry, providing boosts for innovation and making a significant contribution to the development of high-quality products. Their mission is to generate trust in the textiles and leather industry in their production, and to support the path to a sustainable future.

Both dry and wet processing are utilised for fibre production in textile factories. A considerable quantity of potable water is consumed in the wet process and it generates highly contaminated wastewater also in large quantities.

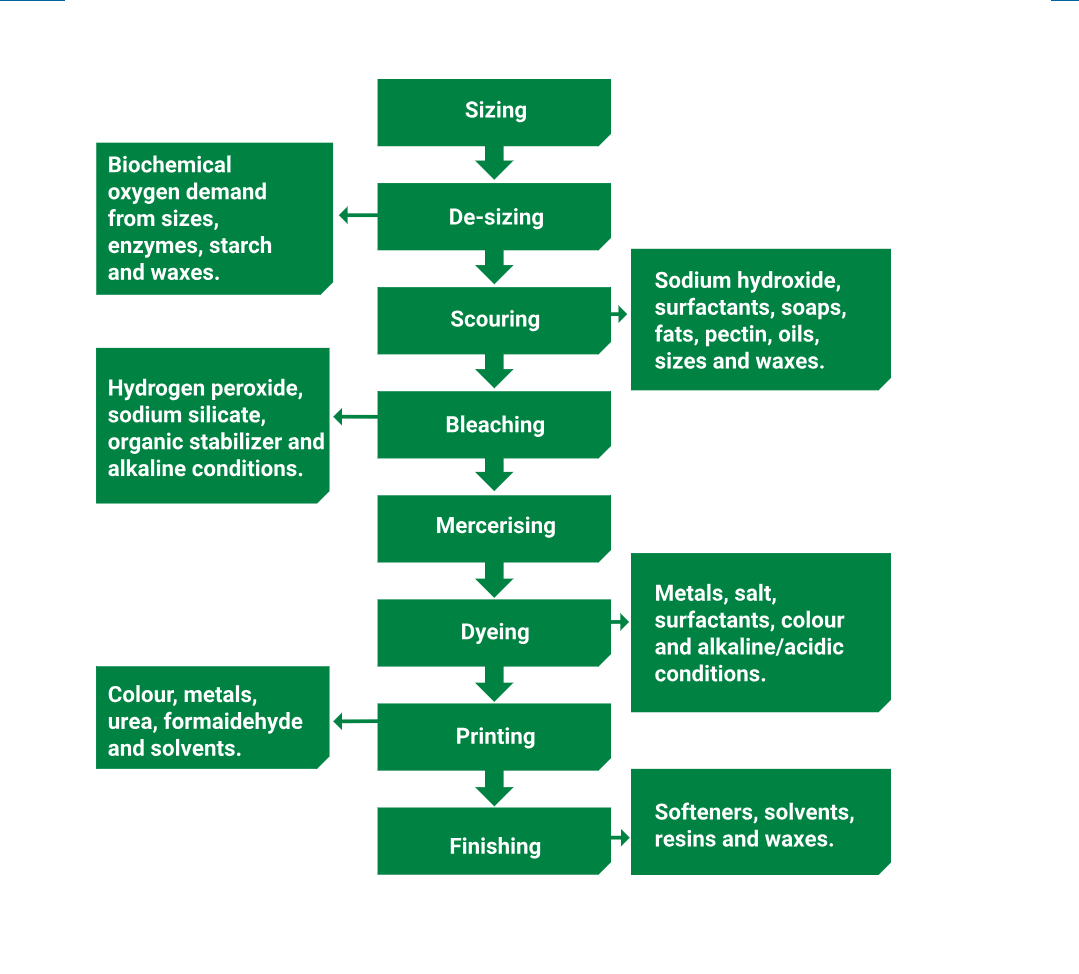

The fibre production process consists of sizing, de-sizing, sourcing, bleaching, mercerising, dyeing, printing and finishing.

Figure shows the main pollutants in the wastewater discharge from each step5.

The dyeing process is an important step in textile manufacturing. During this stage, colour is applied to the fibre, and several chemicals may be used to improve the adsorption process between colour and fibre.